Products

Stainless Steel Wire Rope ine SS316 uye SS304

Product parameters

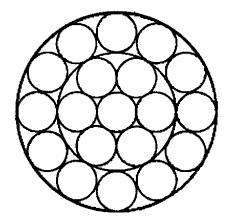

| Kuvaka |

| ||||

| Nominal Diameter | Approximate Weight | Minimum Breaking Load Inoenderana neRope Giredhi Ye | |||

| 1570 | 1670 | 1770 | 1870 | ||

| MM | KG/100M | KN | KN | KN | KN |

| 0.5 | 0.125 | - | 0.255 | - | - |

| 1 | 0.5 | - | 1 | - | - |

| 1.5 | 1.125 | 1.9 | 2.02 | 2.15 | 2.27 |

| 2 | 2 | 3.63 | 3.87 | 4.11 | 4.35 |

| 2.5 | 3.125 | 4.88 | 5.19 | 5.5 | 5.81 |

| 3 | 4.5 | 7.63 | 8.11 | 8.6 | 9.08 |

| 4 | 8 | 12.8 | 13.7 | 14.5 | 15.3 |

| 5 | 12.5 | 19.5 | 20.7 | 22 | 23.2 |

| 6 | 18 | 30.5 | 32.4 | 34.4 | 36.3 |

| 7 | 24.5 | 43.9 | 46.7 | 49.5 | 52.3 |

| 8 | 32 | 51.5 | 54.8 | 58.1 | 61.4 |

| 9 | 40.5 | 68.6 | 73 | 77.4 | 81.7 |

| 10 | 50 | 93.4 | 99.4 | 105 | 111 |

| 11 | 60.5 | 112 | 119 | 126 | 1333 |

| 12 | 72 | 122 | 129 | 137 | 145 |

| Kuvaka |  | ||||

| Nominal Diameter | Approximate Weight | Minimum Breaking Load Inoenderana neRope Giredhi Ye | |||

| 1570 | 1670 | 1770 | 1870 | ||

| MM | KG/100M | KN | KN | KN | KN |

| 1 | 0.51 | 0.83 | 0.88 | 0.93 | 0.99 |

| 1.5 | 1.14 | 1.87 | 1.99 | 2.11 | 2.22 |

| 2 | 2.03 | 3.32 | 3.54 | 3.75 | 3.96 |

| 2.5 | 3.17 | 5.2 | 5.53 | 5.86 | 6.19 |

| 3 | 4.56 | 7.48 | 7.96 | 8.44 | 8.91 |

| 4 | 8.12 | 13.3 | 14.1 | 15 | 15.8 |

| 5 | 12.68 | 20.8 | 22.1 | 23.4 | 24.7 |

| 6 | 18.26 | 29.9 | 31.8 | 33.7 | 35.6 |

| 7 | 24.85 | 40.7 | 43.3 | 45.9 | 48.5 |

| 8 | 32.45 | 53.2 | 56.6 | 60 | 63.4 |

| 9 | 41.07 | 67.4 | 71.6 | 75.9 | 80.2 |

| 10 | 50.71 | 83.2 | 88.5 | 93.8 | 99.1 |

| 11 | 61.36 | 100 | 107 | 113 | 119 |

| 12 | 73.02 | 119 | 127 | 135 | 142 |

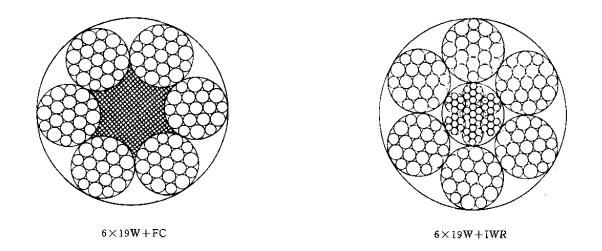

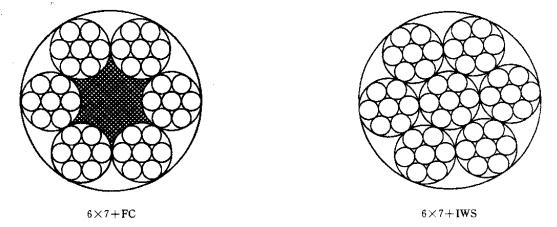

| Kuvaka | ||||||||||

| Nominal Diameter | Approximate Weight | Minimum Breaking Load Inoenderana neRope Giredhi Ye | ||||||||

| Fiber Core | Steel Core | 1570 | 1670 | 1770 | 1870 | |||||

| FC | IWS | FC | IWS | FC | IWS | FC | IWS | FC | IWS | |

| MM | KG/100M | KN |

|

|

|

|

|

|

|

|

| 1.5 | 0.83 | 0.81 | 1.12 | 1.31 | 1.19 | 1.39 | 1.26 | 1.47 | 1.33 | 1.56 |

| 2 | 1.48 | 1.44 | 1.99 | 2.33 | 2.12 | 2.47 | 2.25 | 2.62 | 2.38 | 2.77 |

| 2.5 | 2.31 | 2.25 | 3.12 | 3.64 | 3.32 | 3.87 | 3.51 | 4.1 | 3.71 | 4.33 |

| 3 | 3.32 | 3.24 | 4.49 | 5.24 | 4.78 | 5.57 | 5.06 | 5.91 | 5.35 | 6.24 |

| 4 | 5.9 | 5.76 | 7.99 | 9.32 | 8.5 | 9.91 | 9.01 | 10.51 | 9.52 | 11.1 |

| 5 | 9.23 | 9 | 12.48 | 14.57 | 13.28 | 15.49 | 14.07 | 16.42 | 14.87 | 17.35 |

| 6 | 13.3 | 13 | 18.6 | 20.1 | 19.8 | 21.4 | 21 | 22.6 | 22.2 | 23.9 |

| 8 | 23.6 | 23 | 33.1 | 35.7 | 35.2 | 38 | 37.3 | 40.3 | 39.4 | 42.6 |

| 10 | 36.9 | 36 | 51.8 | 55.8 | 55.1 | 59.4 | 58.4 | 63 | 61.7 | 66.5 |

| 12 | 53.1 | 51.8 | 74.6 | 80.4 | 79.3 | 85.6 | 84.1 | 90.7 | 88.8 | 95.8 |

| 14 | 72.2 | 70.5 | 101 | 109 | 108 | 116 | 114 | 123 | 120 | 130 |

| 16 | 94.4 | 92.1 | 132 | 143 | 141 | 152 | 149 | 161 | 157 | 170 |

| 18 | 119 | 117 | 167 | 181 | 178 | 192 | 189 | 204 | 199 | 215 |

| 20 | 147 | 144 | 207 | 223 | 220 | 237 | 233 | 252 | 246 | 266 |

| Kuvaka | ||||||||||

| Nominal Diameter | Approximate Weight | Minimum Breaking Load Inoenderana neRope Giredhi Ye | ||||||||

| Fiber Core | Steel Core | 1570 | 1670 | 1770 | 1870 | |||||

| FC | IWS | FC | IWS | FC | IWS | FC | IWS | FC | IWS | |

| MM | KG/100M | KN | ||||||||

| 0.5 | 0.092 | 0.09 | 0.127 | 0.149 | 0.135 | 0.158 | 0.144 | 0.168 | 0.152 | 0.177 |

| 1 | 0.367 | 0.36 | 0.511 | 0.596 | 0.543 | 0.634 | 0.576 | 0.672 | 0.608 | 0.71 |

| 1.5 | 0.826 | 0.81 | 1.15 | 1.34 | 1.22 | 1.42 | 1.29 | 1.51 | 1.37 | 1.59 |

| 2 | 1.47 | 1.44 | 2.08 | 2.25 | 2.21 | 2.39 | 2.35 | 2.54 | 2.48 | 2.68 |

| 3 | 3.3 | 3.24 | 4.69 | 5.07 | 4.98 | 5.39 | 5.28 | 5.71 | 5.58 | 6.04 |

| 4 | 5.88 | 5.76 | 8.33 | 9.01 | 8.87 | 9.59 | 9.4 | 10.1 | 9.93 | 10.7 |

| 5 | 9.18 | 9 | 13 | 14 | 13.8 | 14.9 | 14.6 | 15.8 | 15.5 | 16.7 |

| 6 | 13.22 | 12.96 | 18.7 | 20.2 | 19.9 | 21.5 | 21.1 | 22.8 | 22.3 | 24.1 |

| 8 | 23.5 | 23.04 | 33.3 | 36 | 35.4 | 38.3 | 37.6 | 40.6 | 39.7 | 42.9 |

| 10 | 36.72 | 36 | 52.1 | 56.3 | 55.4 | 59.9 | 58.7 | 63.5 | 62 | 67.1 |

| 12 | 52.88 | 51.84 | 75 | 81.1 | 79.8 | 86.3 | 84.6 | 91.5 | 89.4 | 96.6 |

Mapoinzi matanhatu ekutarisisa mukushandiswa kwetambo yesimbi isina tsvina

1.Usashandisa tambo itsva yesimbi isina tsvina zvakananga pakukurumidza uye mutoro unorema

Tambo itsva yesimbi isina tsvina haifaniri kushandiswa zvakananga pakumhanya kukuru uye mutoro unorema, asi inomhanya kwenguva yakati pasi pekumhanya kwakadzika uye mamiriro emutoro wepakati. Mushure mokunge tambo itsva yakagadziriswa kumamiriro ekushandiswa, zvino zvishoma nezvishoma kuwedzera kumhanya kwetambo yetambo uye mutoro unosimudza.

2.The Stainless tambo tambo haigoni disengaged kubva groove

Kana tambo yesimbi isina tsvina ichishandiswa nepulley, ndapota tarisa kuti tambo dzekuchengetedza hadzigone kubviswa kubva papulley groove. Kana tambo yewaya ikaramba ichishanda mushure mekudonha kubva pamukoto wepulley, tambo yewaya inosvinwa nekuremara, kinked, yakatyoka, uye yakatyoka tambo, izvo zvichanyatso kupfupisa hupenyu hwesevhisi hwetambo yetambo. Kana tambo ikadambuka, kazhinji inounza mhedzisiro yakaipa.

3.Usadzvanya tambo yesimbi isina tsvina

Iyo tambo yesimbi isina tsvina haifanirwe kudzvanywa zvakasimba kudzivirira deformation panguva yekushandiswa, kana zvinozotungamira mukutsemuka kwewaya, kuputika kwetambo, kana kutodambuka kwetambo, izvo zvichapfupisa hupenyu hwebasa hwetambo yetambo uye kuisa mungozi kuchengetedzwa kwekushanda.

4.Usazora nezvimwe zvinhu kana tambo yesimbi isina tsvina ichimhanya nekumhanya

Kana tambo yesimbi isina tsvina ichimhanya nekumhanya kukuru, kukweshana kuri pakati petambo yesimbi isina tsvina nezvinhu zviri kunze kwegirovha ndicho chikonzero chikuru chekudambuka kwewaya kwekutanga.

5.Usapeperedza tambo yesimbi isina tsvina zvisina tsarukano

Kana tambo yesimbi isina tsvina yakakuvadzwa padhiramu, inofanira kurongwa zvakanaka sezvinobvira. Kana kuti tambo yesimbi yesimbi ichakuvadzwa panguva yekushanda.Izvi zvichaita kuti tambo inoputika, iyo inobata zvakananga hupenyu hwebasa retambo yesimbi.

6.Usaremedza tambo yesimbi isina tsvina

Kana tambo yesimbi isina tsvina yaremerwa, inokurumidza kuwedzera dhigirii rekudzvanya deformation, uye dhigirii rekupfeka pakati pesimbi yemukati waya uye yekunze simbi waya uye inofananidzira vhiri groove ichaunza kukuvadza kwakakomba kuchengetedzeka kwekushanda uye kupfupisa. hupenyu hwebasa hwepulley.

Application